X-ray

Facility Pages

Radiation Control

Environmental Health Division

Screen Contact Test

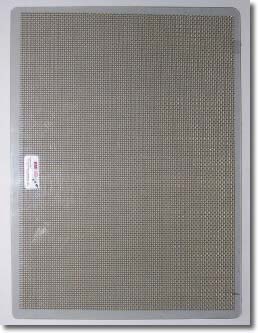

Without good contact between the film and screens of the cassette, detail will be lost on the radiograph. Therefore, it is necessary to routinely perform a screen contact test on all of your cassettes. Screen contact tests are required at intervals not to exceed 24 months, per Minnesota Rule Chapter 4732.1100.

Equipment needed for general radiography

- No significant areas of poor contact as measured by no less than: (1) 8 wires/inch mesh; or (2) 7 holes/inch for regular film; (3) 40 wires/inch mesh or greater for mammography film.

- These test tools are generally encased in acrylic for ease of handling

- Densitometer (if available)

Frequency of test

At intervals not to exceed 24 months

Procedure

- Ensure that cassettes to be tested have been allowed to sit for at least 15 minutes after loading. This will allow for any trapped air to dissipate.

- Place a loaded cassette on top of the x-ray table and place the wire mesh on top of the cassette.

- Select a standard focal film distance (usually 40") and center the x-ray beam to the cassette. (Dental pan cassettes may need a greater distance to cover the full cassette.)

- "Cone down" or restrict the primary beam to the outside edges of the cassette.

- Identify the cassette with lead numbers or letters corresponding to the I.D. on the screen inside. (All screens need identifying marks; e.g., numbers or letters that show up on each radiograph. This enables you to identify which cassette has a problem when one is observed.)

- Select a technique that will produce an optical density of approximately 2.0 on the developed film. For a 400 speed film-screen combination a technique of 65 kVp and 5 mAs is a starting point. Finding a technique to produce the 2.0 (± 0.5 O.D.) may take some trial and error. Remember that cassettes of a different speed (e.g., extremity) will require a different exposure.

Record for future use the technique that produced the appropriate optical density on the film, the room used, and focal-film-distance used.

Record for future use the technique that produced the appropriate optical density on the film, the room used, and focal-film-distance used.- Label, expose and process the film from each cassette.

- View each film on a view box in a dimly lit room from a distance of approximately six feet or more.

- Look for areas that are darker and/or more blurry than the rest of the film. This indicates poor contact. Do not try to identify poor contact by closely looking for fuzzy wires on the film.

- Areas of poor contact need to be evaluated as to their land size. An area of poor contact extending less than an inch from the edge into the film may not be a problem depending on the type of radiographs you take. If the area of poor contact could obscure important information on a radiograph, remove the cassette from service.

Go to > top

Last Updated: 10/15/2024